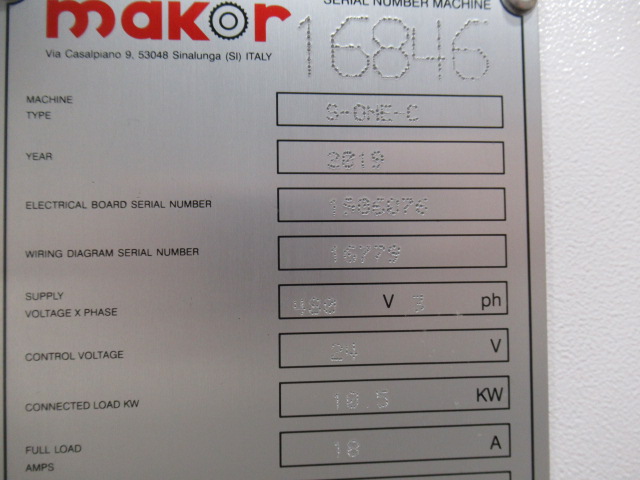

MAKOR START-ONE RECIPROCATING SPRAY MACHINE

- stock number

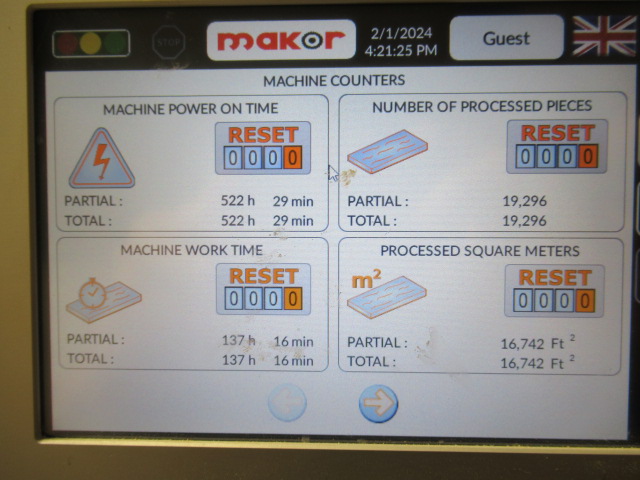

12718 - new/used

Used - year

2019 - fob

SOUTHEAST - electrical

480V, 3 Ph, 60 Cy - condition

ATFS

Share:

Replacement

~$150,000

CostOUR PRICE

Inquire

Have questions?

Prefer to discuss

by phone or email?

We're here to help!

P: 919-776-8341

sales@jgmachinery.com

Description

Flexibility, reliability and ease of use, combined with limited operational cost and investment, enable the START-ONE to be the ideal machine for companies with low volume production applying water based or solvent based paints, or glues.

Advantages offered by the START-ONE: higher production, paint savings, uniform coating, higher and more consistent quality.

PAPER UNROLLING AND REWINDING SYSTEM:

- A paper transport system contributes to a virtually self-cleaning machine and significantly reduces maintenance costs

- The unrolling system at the entrance and the rewinding device at the exit are designed to maintain constant tension of the paper, avoiding breakage even when it is soaked by the paint

- Load/unload of take-up roll is easy due to lateral removal via wheeled trolley

- Rewind station includes a self-adjusting system to maintain a consistently flat paper belt transport (preventing overspray on back side of workpiece)

SPRAYING GROUP:

- Spray system is composed of one oscillating arm with an electronically controlled drive to ensure smooth movement, providing a consistent application across entire working width

- Entire oscillating group is connected to the frame of the machine through pads which guarantee the absolute absence of vibrations, resulting in perfect paint quality on the workpieces

- Spray guns are attached to the oscillating arm using a quick-change gun holding plate with quick disconnects to enable fast replacement of spray guns or for switching between coating circuits

- Four (4) guns can be connected to one of the two (2) paint circuits

- Three (3) high pressure circuits with recycle for coatings

- One (1) high pressure circuit (without return) for solvent

- Coating circuits have return hoses for quickly washing the circuit and for the recirculation of paint

- Two (2) gun holding plates with quick disconnection system to allow fast replacing of the spraying unit

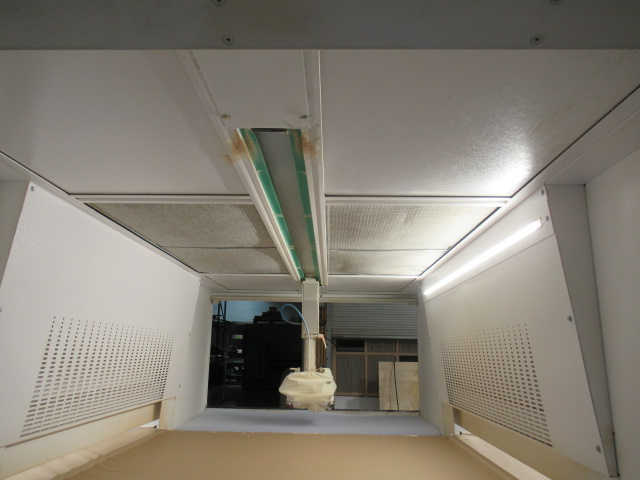

VENTILATION SYSTEM:

- Spray booth design ensures proper control of air flows, avoiding the dispersion of the overspray to the environment

- Pressurization of the spraying zone containing the oscillating mechanism extends its life, improves application quality and minimizes maintenance

- Standard supply provides one (1) gun holding plate with quick disconnection system to allow fast replacing of the spraying unit

- Exhaust fan can be adjusted separately to ensure maximum filter efficiency

- Accessibility is permitted from both sides of the cabin for an easy maintenance

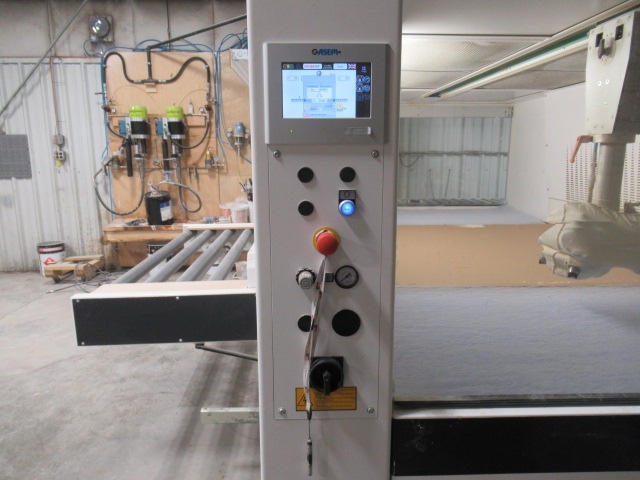

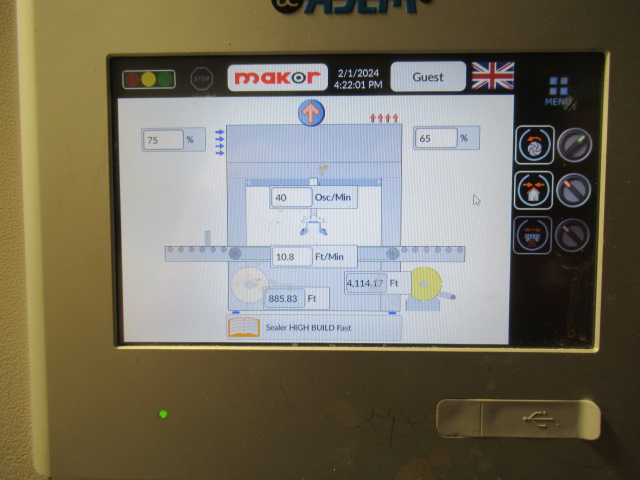

CONTROL SYSTEM:

- Machine is managed by a PLC with a special user interface, that displays and manages in an intuitive way all functions and working parameters

- An electronic reading bar automatically detects workpiece dimensions as they enter the machine to control the spray gun activation (optimize consumption of paint)

OPTIONS INCLUDED:

- Quick Change Design

- Rapid (manual) coating change-over system enables the operator to cease operation on active circuit, flush guns with solvent, activate the next circuit and then purge first circuit while machine is already in operation on the second circuit

- Three (3) high pressure coating circuits with recycle (closed-loop)

- One (1) high pressure circuit for solvent

- One (1) 5-way manual valve for active circuit selection

BOOTH PRESSURIZATION UNIT:

- Pressurization unit complete with two (2) intake fans and removable filters to pressurize the spray booth

- Spare Quick Change High Pressure Gun Holding Plate

- One (1) spare high-pressure gun holding plate (two (2) total)

- Includes (8) Kremlin AVX auto guns, (2) Kremlin 20:50 wall mount pumps complete, and (2) Kremlin fluid regulators

- Also includes (3) spare paper feed rolls

PRODUCT DIMENSIONS:

- Substrates having the following approximate maximum and minimum dimensions can be transported through the equipment offered:

- Length: maximum n/a, minimum 12"

- Width: maximum 51", minimum 1"

- Height: maximum 2-3/8", minimum 3/16"

TECHNICAL SPECIFICATIONS:

- Overall dimensions: 149" X 100" X 141"

- Feed speed: 3.3 to 14.75 FPM

- Feed motor power: 1 HP

- Reciprocator motor power: 2.5 HP

- Pressurization fan motor: 4 HP

- Exhaust air fan motor power: 4 Skw

- Operating voltage: 480V 3-phase 60 hz

- Total connected load: 10.2 kW

- Exhaust air volume: 10,000 m3/hr (5,885 CFM)

- Air make up required: 10,000 m3/hr (5,885 CFM)

- Compressed air: 6 bar (90 psi)

- Consumption/ volume: 1,650 nl/hr (58.3 CFM)

- Voltage supplied must not fluctuate in excess of +/- 5 percent of its stated value. Voltage must be balanced phase-to phase and phase-to-ground.

Prices and specifications are subject to change without notice. Dimensions and weights do not include crates or packaging. We measure and weigh each machine and/or crate prior to shipping and will be happy to provide this information to you upon request.

Connect with us